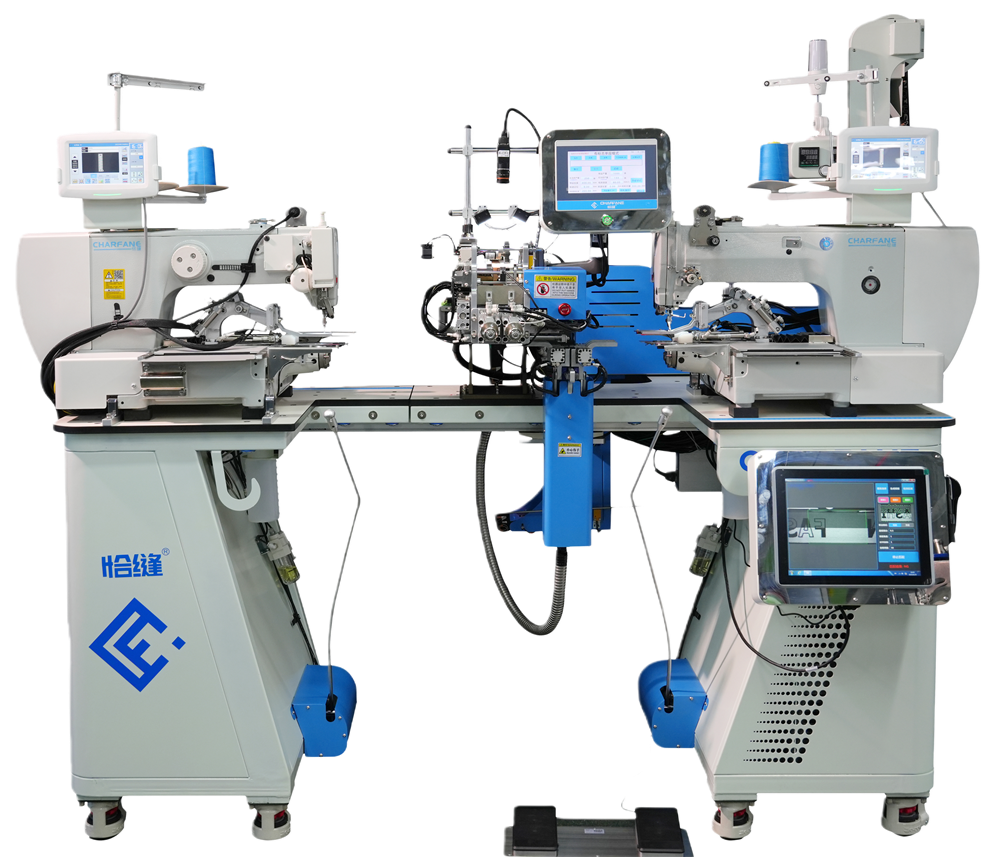

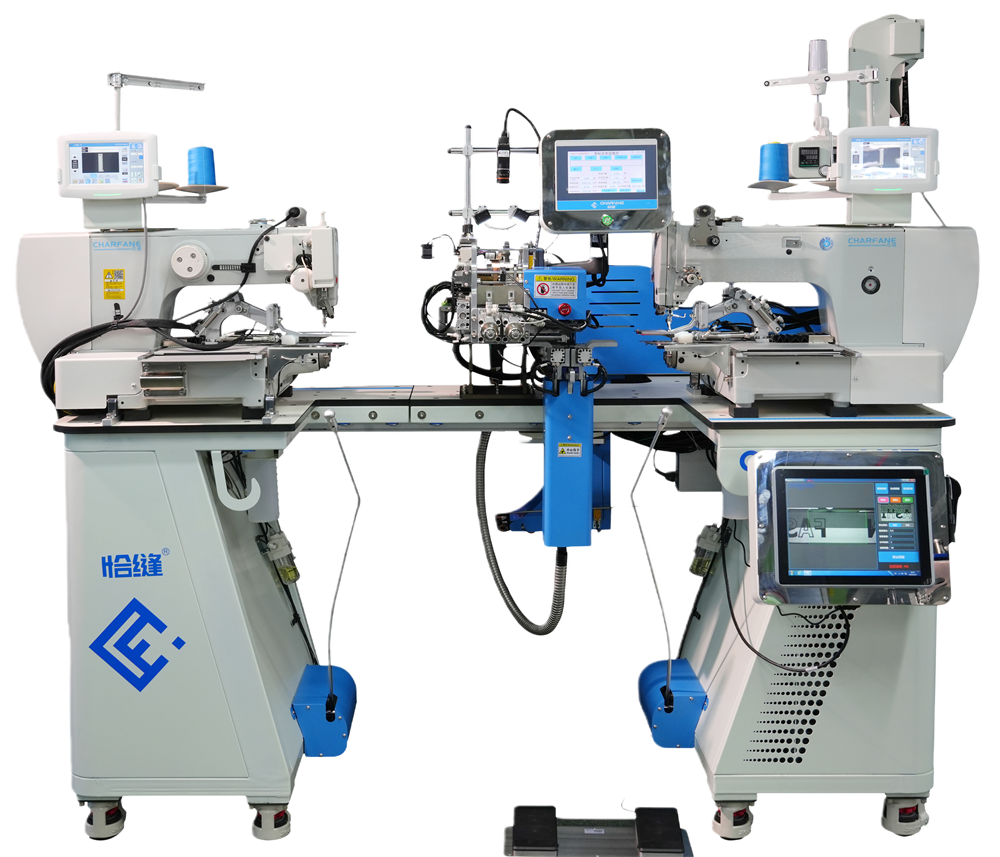

Double-head Automatic Elastic Thread Sewing Machine -- Vision Edition

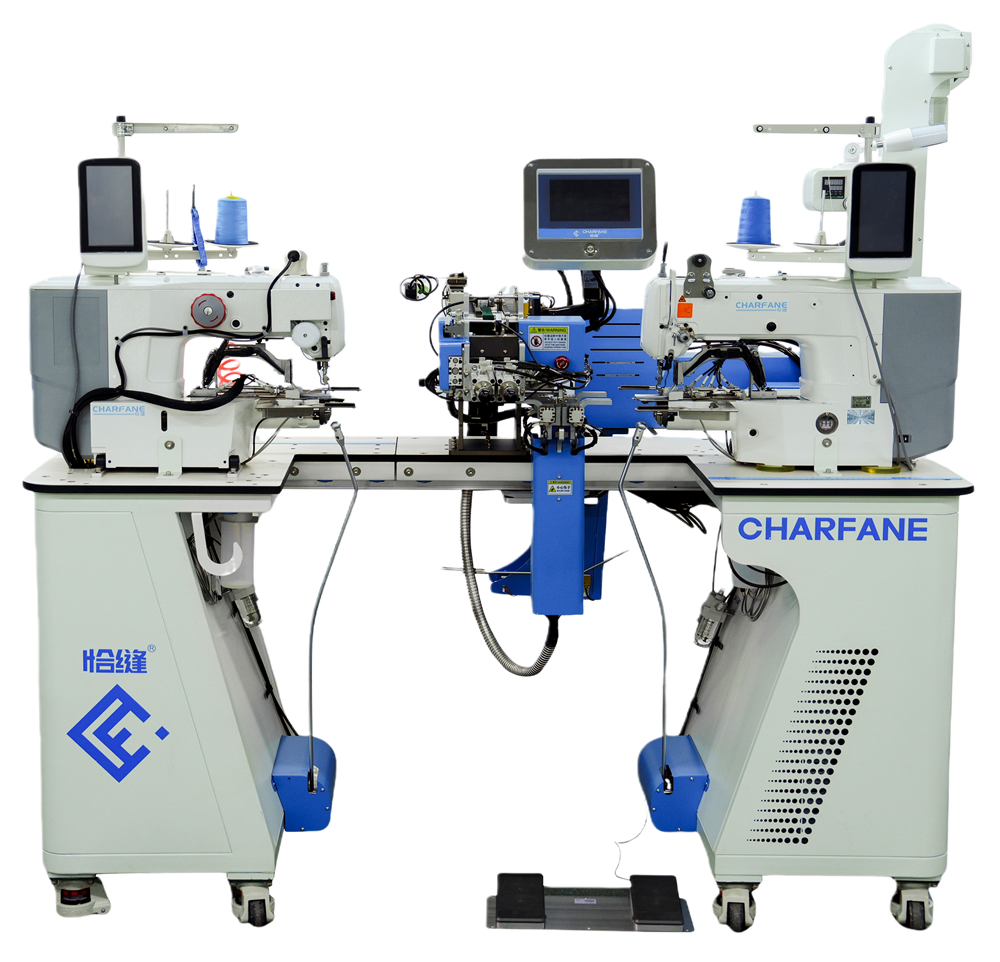

Double-head Automatic Elastic Thread Sewing Machine -- Non-Vision Edition

1、The machine adopts a dual-head sewing mechanism, doubling the efficiency

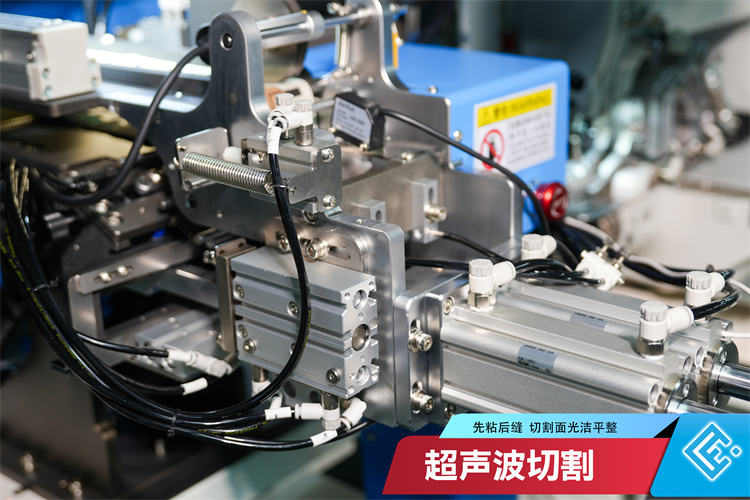

2、The sewing process involves ultrasonic bonding first, followed by head sewing, resulting in a smoother joint

3、Equipped with Industrial Internet of Things (IIoT) technology, it enables remote data updates and system iteration to maintain optimal software performance for the equipment

4、It supports remote parameter adjustments and cloud-based equipment fault maintenance, significantly improving after-sales service efficiency and truly delivering an ultra-fast after-sales service experience

5、It connects via a mobile app to view equipment data (such as operating hours, machine output, etc.) and operational status, enabling rapid data interaction

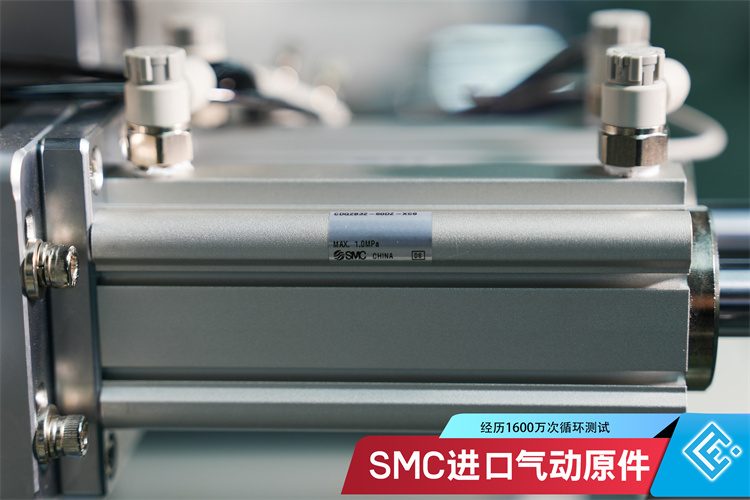

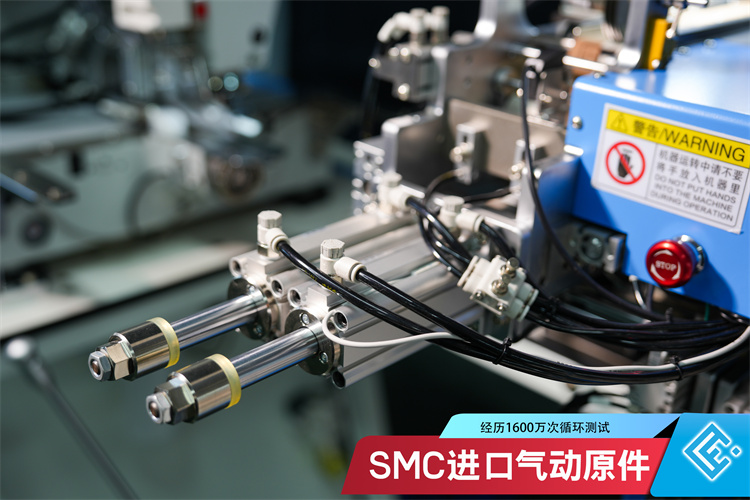

6、The machine utilizes imported SMC electrical components for faster operation, delivering enhanced stability and durability

7、Logo positioning function: utilizes a color-based positioning system to accurately locate single or multiple Logo positions

8、The shaping/feeding device is equipped with infrared sensors and a heating pre-shrinkage function. This helps eliminate creases in the raw material, resulting in a smoother and more aesthetically pleasing finished product. Additionally, the use of infrared sensing prevents elastic bands from deforming due to excessive tension during the feeding process

9、It features automatic alarm and shutdown functions for thread breakage and bobbin run-out

10、The material collection function allows the quantity per bundle to be set as needed and enables automatic collection, significantly improving work efficiency

11、Intelligent length control ensures an accuracy margin within 2 millimeters

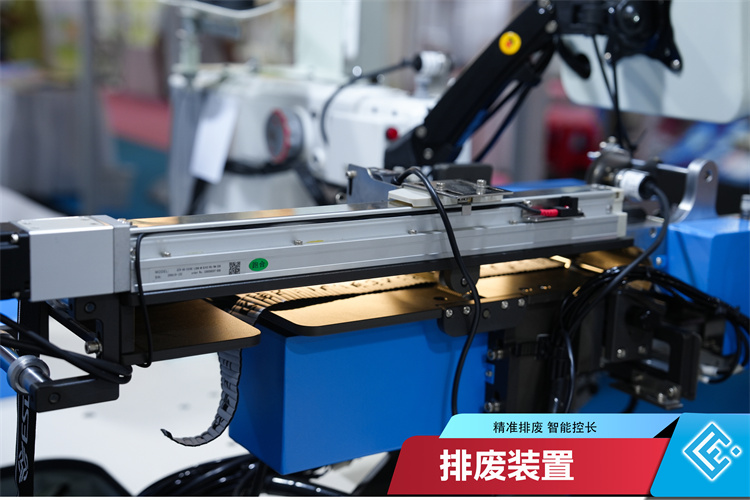

12、The added infrared sensor prevents continuous feeding malfunctions when the top thread fails to be cut

13、The elastic band splice can be automatically detected and rejected, while also protecting the cutting blade

It has undergone 16 million cycle tests

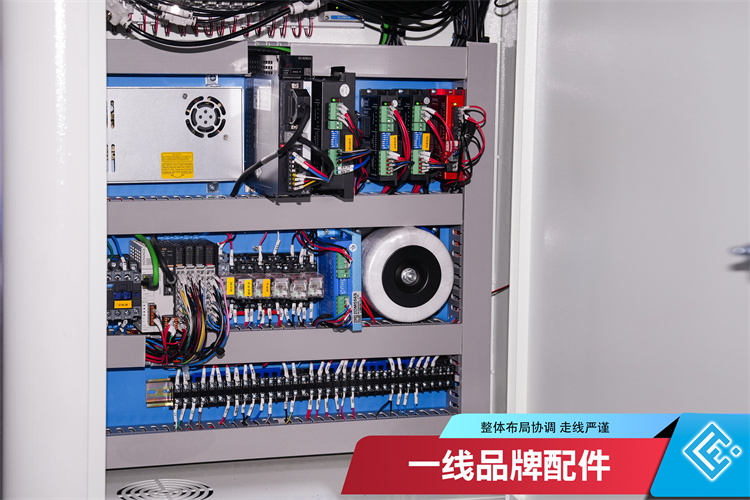

The overall layout is harmonious with precise wiring

Precise waste discharge and intelligent length control

Automatic detection and shutdown functions for top thread breakage and bobbin run-out

Ironing out wrinkles for a more aesthetically pleasing finished product

Significantly reduces needle breakage and thread breakage rates

Bond first, then sew—the cut surface is smooth and neat

High sensitivity with multiple pattern options available

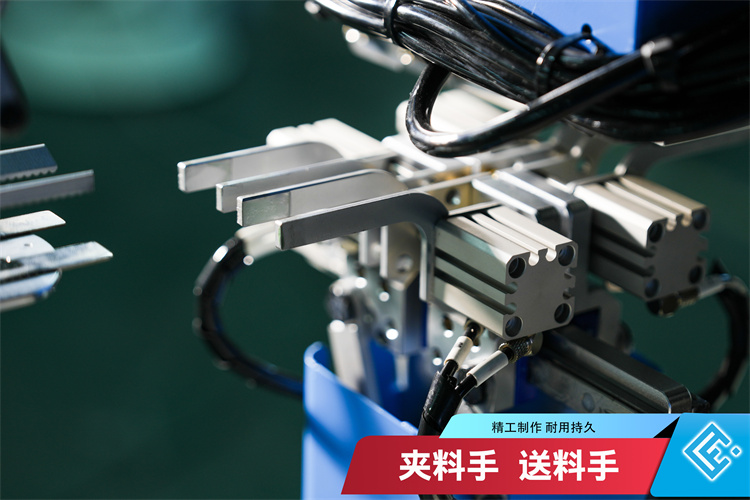

Precision craftsmanship ensures durability and longevity

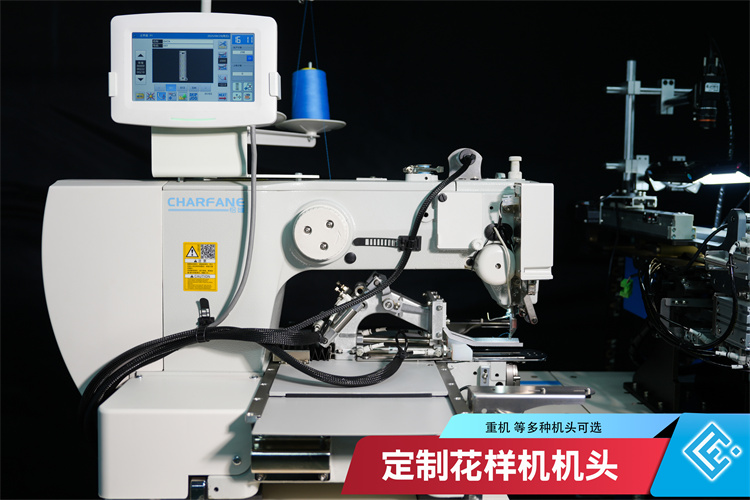

Multiple head options available, including Juki among others

Precise visual alignment for same-color, embossed 3D LOGOs

Precise length control with an error margin of less than 2mm

| MODEL | F-560-U2 | F-560H-U2 | F-720-U2 | F-750-U2 |

| CUTTING TOOL | Ultrasonic Cutting | Ultrasonic Cutting | Ultrasonic Cutting | Ultrasonic Cutting |

| ELASTIC WIDTH | 1-6CM | 1-7CM | 1-8CM | 1-8CM |

| ELASTIC LENGTH | 22-300CM | 22-300CM | 22-300CM | 22-300CM |

| NEEDLE(DP*17) | #11-16 | #11-16 | #11-16 | #11-16 |

| SPEED | 2000 | 2300 | 2000 | 2500 |

| VISUAL MATCHING | M | M | M | M |

| VOLUME | 210X121X160CM | 210X121X160CM | 210X121X160CM | 210X121X160CM |

| GROSS/NET WEIGHT | 794KG/674KG | 794KG/674KG | 840KG/720KG | 840KG/720KG |

Address: No. 18 Shengda North Street, Chengxi Street, Yiwu City, China (Zhejiang) Pilot Free Trade Zone (Room 501, 5th Floor, Zhejiang Jinge Knitting Co., Ltd.) (self declared)

Mobile: +86-15957992256

E-mail: 1097894196@qq.com

Copyright © Zhejiang Chashan Technology Co., Ltd