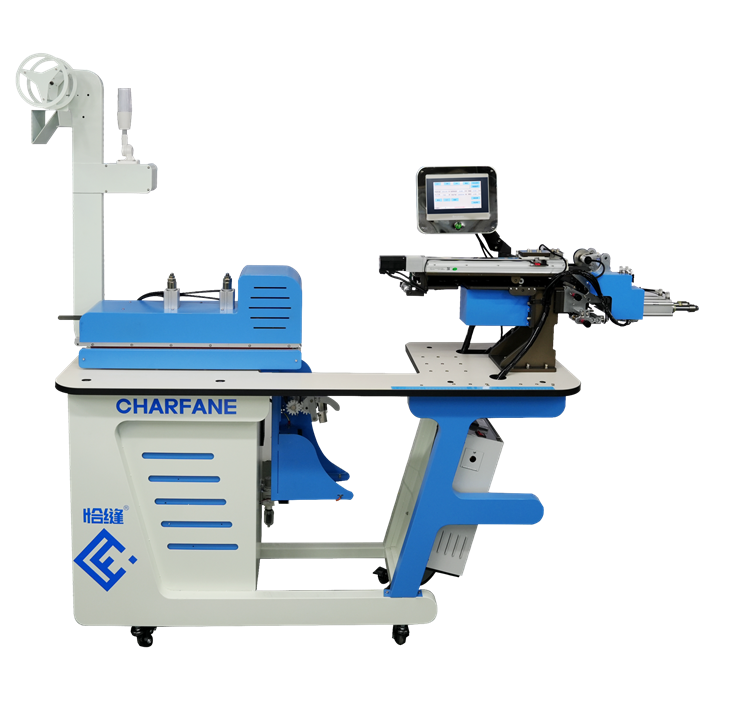

1、Equipped with Industrial IoT technology to enable remote software updates, ensuring the machine's software is always optimized for peak performance

2、It supports remote parameter adjustment and cloud-based diagnostics, significantly boosting service efficiency and enabling a rapid-response support experience

3、Seamlessly connect via a mobile app to access real-time equipment data—such as working hours and production output—and operational status, enabling swift data interaction

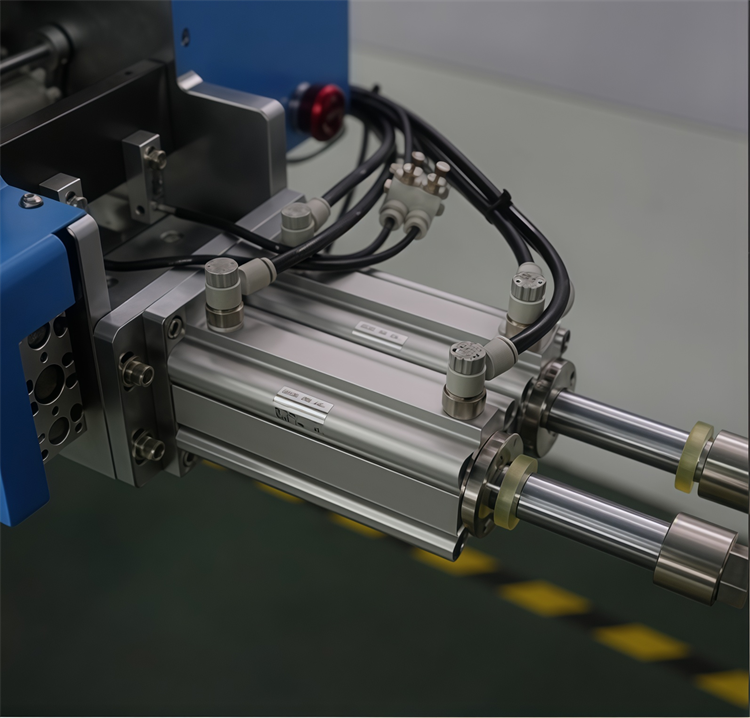

4、It utilizes imported SMC pneumatic components for higher operating speed, enhanced stability, and greater durability

5、The logo positioning function utilizes a color recognition system to precisely locate the placement of single or multiple logos

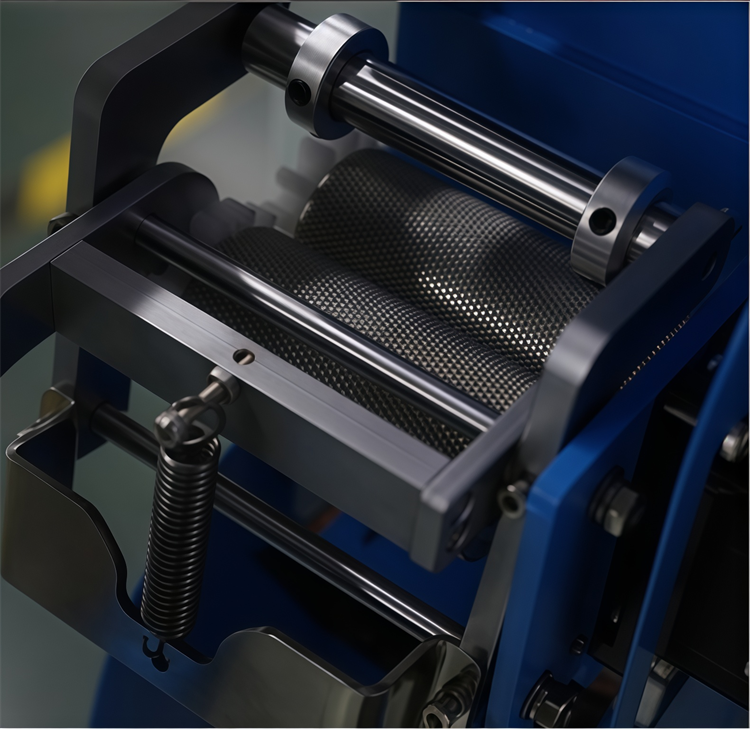

6、The shaping/feeding unit is equipped with an infrared sensor and a heating function. The heater smooths out wrinkles in the material for a superior finish, while the infrared feedback prevents elastic deformation by maintaining consistent tension during feeding

7、A specialized ultrasonic unit simultaneously cuts and welds the tape, creating a seamlessly bonded edge

8、It features intelligent length control for cutting or sewing, maintaining a precision tolerance within 2 mm

9、It automatically detects and rejects elastic band splices, thereby protecting the cutting blade from damage

| MODEL | F-620-UW |

| CUTTING METHOD | Ultrasonic Welding |

| ELASTIC WIDTH | 2-6CM |

| ELASTIC LENGTH | 5-200CM |

| POWER | 1500W |

| SPEED(PIECES/HOUR) | 2000~3000 |

| VISUAL MATCHING | Optional |

| VOLUME | 185X61X145CM |

| GROSS/NET WEIGHT | 230KG/190KG |

Address: No. 18 Shengda North Street, Chengxi Street, Yiwu City, China (Zhejiang) Pilot Free Trade Zone (Room 501, 5th Floor, Zhejiang Jinge Knitting Co., Ltd.) (self declared)

Mobile: +86-15957992256

E-mail: 1097894196@qq.com

Copyright © Zhejiang Chashan Technology Co., Ltd