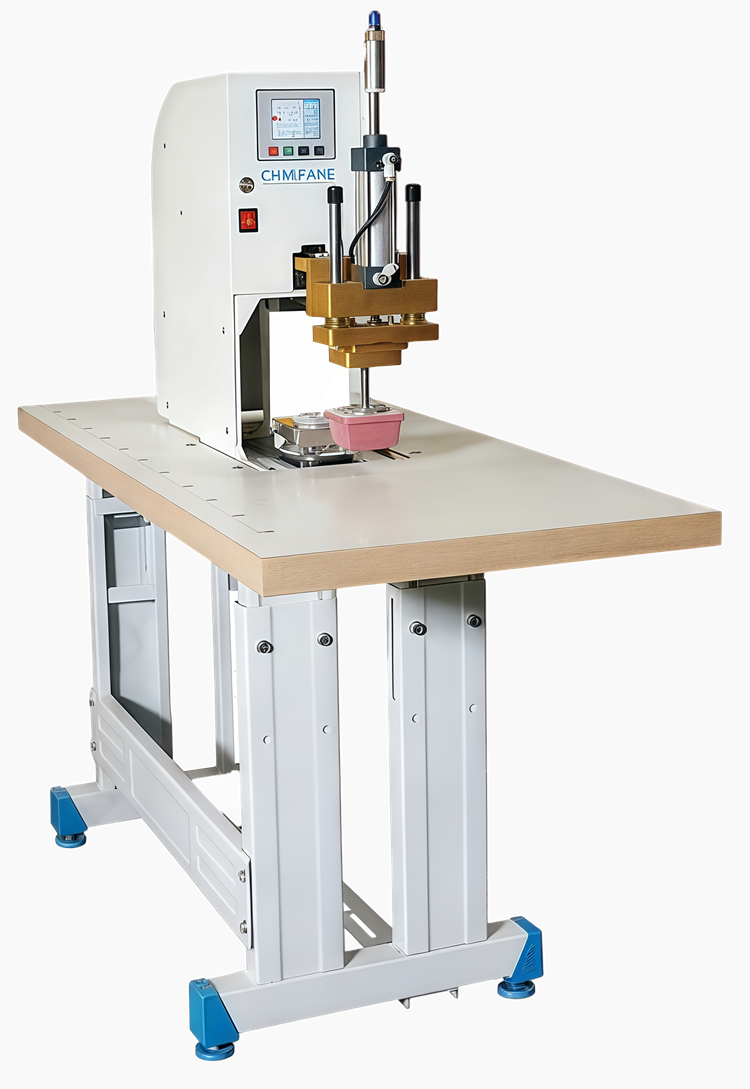

Ease of use

The production mode can be easily switched between manual and semi-automatic to suit different fabrics and requirements, allowing for greater operational flexibility

High efficiency

A capacity of 1,000 units per hour, achieving three times the speed of traditional heat transfer printing

Safety

The process involves no heating or pressing, eliminating the risks of burns and crush injuries, thereby significantly enhancing operator safety

Low consumable consumption

While traditional heat transfer labels incur significant costs, the specialized ink used in pad printing results in a negligible expense

Low power consumption

Traditional heat transfer requires a minimum power of 15 kW, consuming 1.5 kWh per hour, whereas a pad printing machine uses only 0.3 kWh per hour

Value formula

1、The efficiency gain delivers significant labor savings: while traditional heat transfer achieves about 300 units/hour, the CHARFANE Pad Printer reaches 1,000 units/hour—a threefold increase. This translates to a reduction of 2 operators, resulting in estimated annual labor cost savings of 100,000 RMB

2、Significant cost savings on consumables: Based on an annual production of 1 million garments, traditional heat transfer labels at 0.1 RMB each would cost 100,000 RMB, whereas the CHARFANE Pad Printing Machine requires only 2 kg of ink costing 220 RMB, leading to projected annual material savings of nearly 100,000 RMB

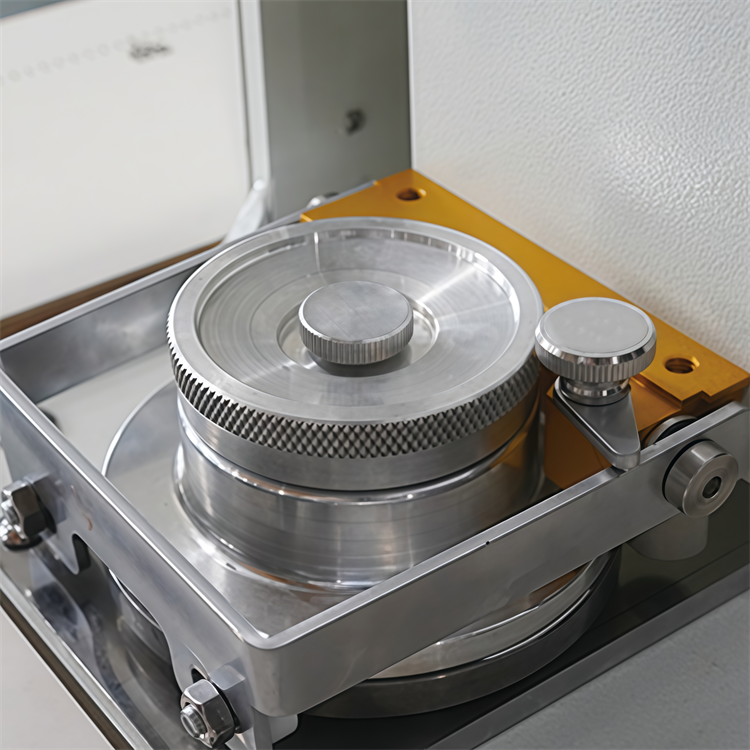

| 使用必备清单 | ||

| 序号 | 名称 | 单位 |

| 1 | 移印模板 | 块 |

| 2 | 油墨 | 瓶 |

| 3 | 油墨 | 瓶 |

| 4 | 固化剂 | 瓶 |

| 5 | 除味剂 | 瓶 |

Address: No. 18 Shengda North Street, Chengxi Street, Yiwu City, China (Zhejiang) Pilot Free Trade Zone (Room 501, 5th Floor, Zhejiang Jinge Knitting Co., Ltd.) (self declared)

Mobile: +86-15957992256

E-mail: 1097894196@qq.com

Copyright © Zhejiang Chashan Technology Co., Ltd