1、As the fruit of a strategic partnership between JUKI and CHARFANE, this machine incorporates the renowned JUKI AMS-210EN sewing head, delivering superior stitch quality and reliability

2、Industrial IoT technology is integrated, enabling remote updates and system iteration for continuous performance optimization of the device software

3、It enables remote parameter adjustments and cloud-based diagnostics, significantly improving after-sales efficiency and delivering a rapid-response support experience

4、The system allows for mobile app integration to monitor equipment data (e.g., operating time, machine output) and runtime status, facilitating quick data exchange

5、Imported SMC pneumatic components are adopted, which translate into faster operation, improved stability, and better longevity

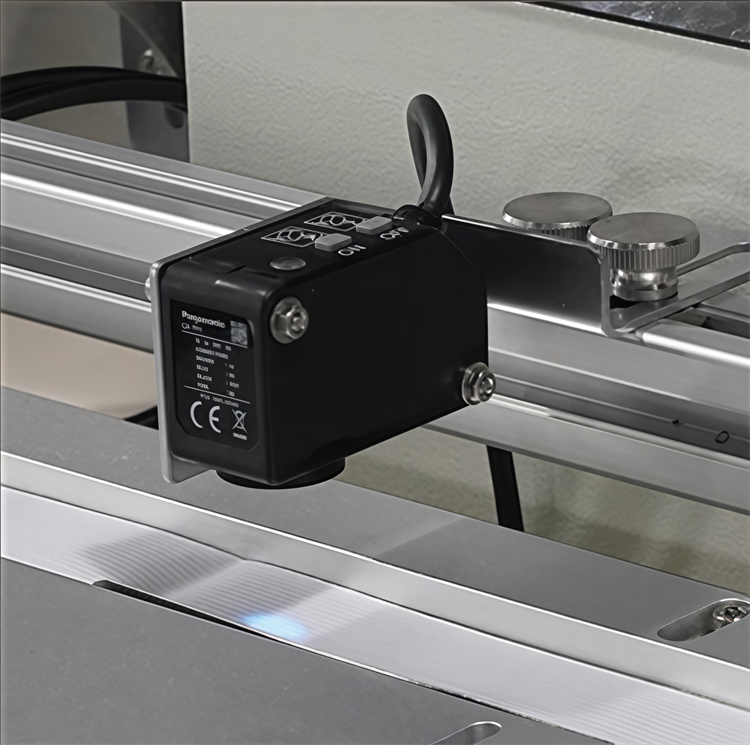

6、The system is equipped with a color-based positioning function that enables accurate placement of individual or multiple logos

7、The system incorporates an infrared-sensing feeding and shaping device. This device includes a heating function designed to remove creases from the raw material, enhancing the product's appearance, and uses infrared monitoring to prevent deformation of the elastic tape due to high feeding tension

8、It features an automatic alarm and stop function for broken needles and an empty bobbin

9、The system is equipped with an automatic collection function. It can be set to stack materials into bundles of a required size, dramatically improving work efficiency

10、The length is intelligently controlled with a deviation of less than 2 mm

11、An added infrared sensor prevents the machine from feeding material when a thread trimming failure occurs, effectively avoiding jams and damage

12、It automatically detects and rejects elastic band splices, thereby protecting the cutting blade from damage

The fruit of a strategic partnership between JUKI and CHARFANE

Equipped with the JUKI AMS-210EN sewing head, which ensures excellent sewing results

Premium electrical components from top-tier industry suppliers

Utilizes imported SMC pneumatic components for increased speed, enhanced stability, and superior durability

Equipped with a logo vision system for automatic positioning

Its color recognition system precisely locates single or multiple logos, effectively enhancing product quality

Industrial Internet of Things

1、It enables remote data updates and system upgrades to ensure the device software remains in its optimal state

2、It supports remote parameter adjustments and cloud-based diagnostics, significantly improving after-sales efficiency and delivering a rapid-response support experience

3、Seamless connectivity via a mobile app allows for real-time access to equipment data (e.g., operating hours, production output), operational status, and rapid data interaction

IR-sensed Elastic Shaping Unit

The specially designed elastic shaping chamber effectively smoothes out wrinkles in the raw material for a superior finish, while its integrated infrared sensor maintains optimal tension to prevent deformation during feeding

Hands-free Automation

1、Automatic alarm and stop function for broken needles and empty bobbins

2、An auto-stacker with a programmable batch count, enabling extended periods of automated sewing

3、It intelligently and precisely controls the elastic loop length, minimizing measurement errors with a one-time setup that eliminates subsequent adjustments

4、An added auto-sensing device prevents material feed during thread trimming failures, thereby reducing material waste

5、Automatic detection and rejection of elastic splices for material savings, higher efficiency, and cutter protection

| MODEL | F-750-L | F-750-U |

| CUTTING TOOL | Gantry Cutter | Ultrasonic Cutting |

| ELASTIC WIDTH | 1-8CM | 1-8CM |

| ELASTIC LENGTH | 20-300CM | 20-300CM |

| NEEDLE(DP*17) | #11-16 | #11-16 |

| SPEED | 2500 | 2500 |

| VISUAL MATCHING | M | M |

| VOLUME | 176X121X146CM | 176X121X146CM |

| GROSS/NET WEIGHT | 391KG/297KG | 443KG/349KG |

Address: No. 18 Shengda North Street, Chengxi Street, Yiwu City, China (Zhejiang) Pilot Free Trade Zone (Room 501, 5th Floor, Zhejiang Jinge Knitting Co., Ltd.) (self declared)

Mobile: +86-15957992256

E-mail: 1097894196@qq.com

Copyright © Zhejiang Chashan Technology Co., Ltd